Tape Splicing Products

SMT Carrier Tape Use Splice Cover Tape

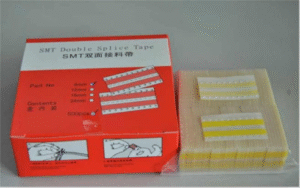

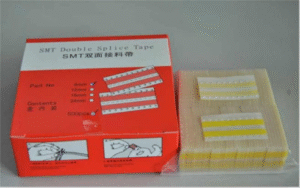

Splice Tape

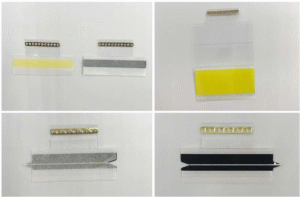

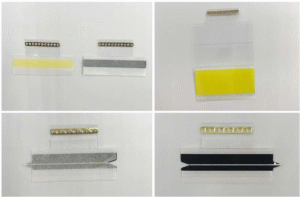

SMT 8mm Splice Tape

SMT 12mm Splice Tape

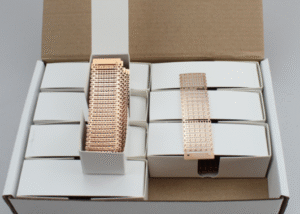

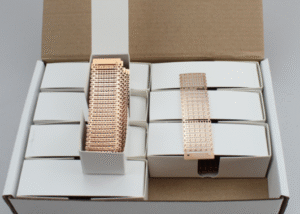

Copper buckle tapes

SMT Splice Tape: The Unsung Hero of Uninterrupted Production

In the high-velocity environment of Surface Mount Technology (SMT) assembly, downtime is the enemy of efficiency. A key vulnerability in continuous production is the moment a component reel runs out. This is where SMT Splice Tape (also known as Splicing Tape or Leader Tape) plays a critical, though often overlooked, role. It is a simple yet ingenious solution that ensures the seamless flow of components from reel to reel, keeping pick-and-place machines running without pause.

What is SMT Splice Tape?

SMT Splice Tape is a specialized, double-sided adhesive tape designed to connect the end of a nearly empty component reel to the beginning of a new reel. Components are supplied on a carrier tape, which consists of a pocketed base tape and a top cover tape that protects the components.

When the original reel is exhausted, instead of stopping the machine to load a new feeder, an operator uses splice tape to join the two tapes together. This creates a continuous “bridge,” allowing the machine to feed directly from the new reel without interruption.

Why is it Essential?

The primary value of splice tape is maximizing machine uptime. In a high-mix or high-volume production environment, the few minutes it takes to stop, unload an empty feeder, and load a new one can add up to significant production losses over time. Splicing reels together offline and then loading a single, continuous reel eliminates these frequent stoppages.

This leads directly to:

Increased Overall Equipment Effectiveness (OEE): By reducing setup and changeover time.

Higher Production Throughput: More boards can be assembled per shift.

Reduced Operator Labor: Operators spend less time constantly monitoring and changing reels.

Key Characteristics and Technical Requirements

Not just any double-sided tape can be used. SMT Splice Tape must meet stringent requirements to function reliably in a precision manufacturing process:

Precise Thickness: The tape must be thin enough (typically under 100µm) to pass smoothly through the feeder’s guide path without causing jams, snags, or triggering feeder errors. It must not create a “bump” that disrupts the tape’s travel.

Strong and Instant Adhesion: The adhesive bond must be immediately strong and durable enough to withstand the high peeling force of the cover tape being ripped back and the pulling tension of the feeder’s advance mechanism. It must not break during operation.

Punch-Through Resistance: A critical property. When the feeder advances the tape, a sprocket gear engages with the indexing holes on the side of the carrier tape. The splice tape must be strong enough to resist tearing or “punching through” under this mechanical force. Special splicing sleeves or splicing patches are often used to reinforce this area.

Heat Resistance: The tape must not leave a sticky adhesive residue on the feeder’s critical parts, such as the cover tape peeler blade or the guide rails, even under slight frictional heat.

Static-Safe: The materials used in its construction should be anti-static to prevent damage to sensitive electronic components from Electrostatic Discharge (ESD).

The Splicing Process: A Quick Overview

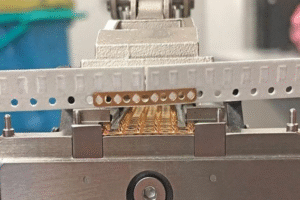

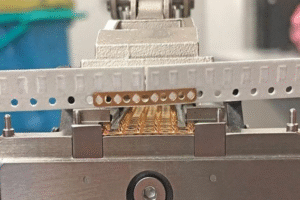

The process is typically performed using a dedicated splicing machine or a manual splicing tool for precision and consistency:

The end of the old reel and the start of the new reel are cut straight and aligned.

The cover tape is peeled back from both ends.

A piece of splice tape is applied across the joint, bonding the two base tapes together.

A reinforcing sleeve is often applied over the sprocket holes for added strength.

The cover tape from the new reel is laid over the spliced section.

The newly created master reel is then loaded onto the feeder, and production continues uninterrupted.

Conclusion

While SMT Splice Tape is a low-cost consumable, its role is strategically vital. It is a key enabler of lean manufacturing principles in electronics assembly, directly combating waste in the form of waiting and unnecessary motion. By ensuring a non-stop supply of components, this humble tape safeguards productivity, making it an indispensable tool in any modern, efficiency-driven SMT factory.

Share to:

Tape Splicing Products

SMT Carrier Tape Use Splice Cover Tape

Splice Tape

SMT 8mm Splice Tape

SMT 12mm Splice Tape

Copper buckle tapes

SMT Splice Tape: The Unsung Hero of Uninterrupted Production

In the high-velocity environment of Surface Mount Technology (SMT) assembly, downtime is the enemy of efficiency. A key vulnerability in continuous production is the moment a component reel runs out. This is where SMT Splice Tape (also known as Splicing Tape or Leader Tape) plays a critical, though often overlooked, role. It is a simple yet ingenious solution that ensures the seamless flow of components from reel to reel, keeping pick-and-place machines running without pause.

What is SMT Splice Tape?

SMT Splice Tape is a specialized, double-sided adhesive tape designed to connect the end of a nearly empty component reel to the beginning of a new reel. Components are supplied on a carrier tape, which consists of a pocketed base tape and a top cover tape that protects the components.

When the original reel is exhausted, instead of stopping the machine to load a new feeder, an operator uses splice tape to join the two tapes together. This creates a continuous “bridge,” allowing the machine to feed directly from the new reel without interruption.

Why is it Essential?

The primary value of splice tape is maximizing machine uptime. In a high-mix or high-volume production environment, the few minutes it takes to stop, unload an empty feeder, and load a new one can add up to significant production losses over time. Splicing reels together offline and then loading a single, continuous reel eliminates these frequent stoppages.

This leads directly to:

Increased Overall Equipment Effectiveness (OEE): By reducing setup and changeover time.

Higher Production Throughput: More boards can be assembled per shift.

Reduced Operator Labor: Operators spend less time constantly monitoring and changing reels.

Key Characteristics and Technical Requirements

Not just any double-sided tape can be used. SMT Splice Tape must meet stringent requirements to function reliably in a precision manufacturing process:

Precise Thickness: The tape must be thin enough (typically under 100µm) to pass smoothly through the feeder’s guide path without causing jams, snags, or triggering feeder errors. It must not create a “bump” that disrupts the tape’s travel.

Strong and Instant Adhesion: The adhesive bond must be immediately strong and durable enough to withstand the high peeling force of the cover tape being ripped back and the pulling tension of the feeder’s advance mechanism. It must not break during operation.

Punch-Through Resistance: A critical property. When the feeder advances the tape, a sprocket gear engages with the indexing holes on the side of the carrier tape. The splice tape must be strong enough to resist tearing or “punching through” under this mechanical force. Special splicing sleeves or splicing patches are often used to reinforce this area.

Heat Resistance: The tape must not leave a sticky adhesive residue on the feeder’s critical parts, such as the cover tape peeler blade or the guide rails, even under slight frictional heat.

Static-Safe: The materials used in its construction should be anti-static to prevent damage to sensitive electronic components from Electrostatic Discharge (ESD).

The Splicing Process: A Quick Overview

The process is typically performed using a dedicated splicing machine or a manual splicing tool for precision and consistency:

The end of the old reel and the start of the new reel are cut straight and aligned.

The cover tape is peeled back from both ends.

A piece of splice tape is applied across the joint, bonding the two base tapes together.

A reinforcing sleeve is often applied over the sprocket holes for added strength.

The cover tape from the new reel is laid over the spliced section.

The newly created master reel is then loaded onto the feeder, and production continues uninterrupted.

Conclusion

While SMT Splice Tape is a low-cost consumable, its role is strategically vital. It is a key enabler of lean manufacturing principles in electronics assembly, directly combating waste in the form of waiting and unnecessary motion. By ensuring a non-stop supply of components, this humble tape safeguards productivity, making it an indispensable tool in any modern, efficiency-driven SMT factory.

LCX Copyright © 2026 All Rights Reserved.